Valve alloy LF2 (LF2 valve alloy) for high performance internal

combustion engine exhaust valve

PRODUCT

Alloy LF2 (LF2 valve alloy) for high performance internal

combustion engine (diesel engine and gasoline engine) exhaust

valves for automobile, locomotive, tractor, ship, tank, oil rig,

construction machinery and mobile power station, etc.

PRODUCT FORM

Bar and rod: the delivery condition is rolled, heat treated,

oxidation, descaling, turned, ground, and polished, etc.

Others: disc, seamless pipe and tube, cylinder, forging, forging

block etc.

APPLICATION

Alloy LF2 is mainly used as the exhaust valve material for

high-power internal combustion engines such as heavy duty diesel

engines.

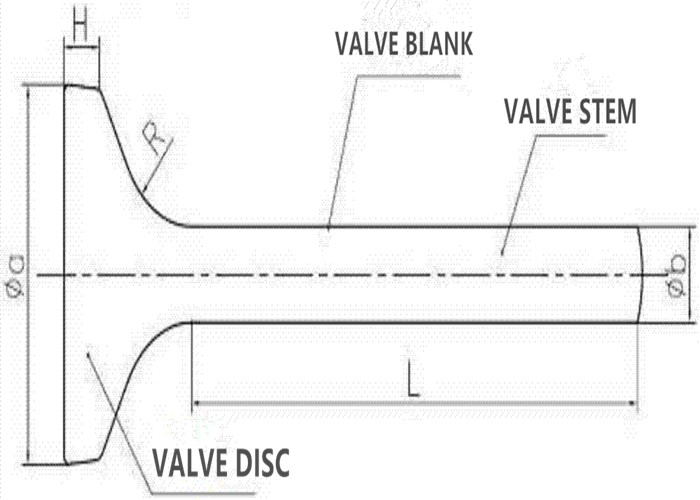

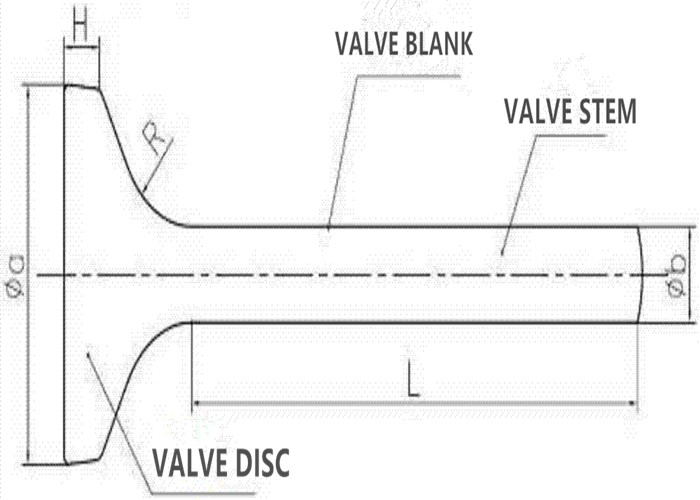

SKETCH OF EXHAUST VALVE

PRODUCTION PROCEDURE OF EXHAUST VALVE

Blanking → Electric heating upsetting forging of head blank → Heat

treatment of head blank and rod → Friction welding → Rough turning

or grinding → Finish turning → Cut fixed length → Semi-fine

grinding the stem → The valve stem chrome plating → Fine grinding

the stem → NDT of the finished valve → Delivery

SURFACE CONDITION OF EXHAUST VALVE

PRODUCTION SITE OF EXHAUST VALVE

CHEMICAL COMPOSITION (wt%):

| Fe | Ni | Co | Cr | Zr | Ti | Nb | Ce |

| Balance | 20.0-28.0 | 0.10-3.0 | 17.0-23.0 | 0.01-0.20 | 1.80-3.20 | 0.70-2.00 | 0.003-0.10 |

| Cu | C | Al | Mn | Si | P | S | |

| 0.05-0.50 | 0.02-0.20 | 0.70-2.00 | 0.40-1.50 | 0.10-1.50 | ≤0.015 | ≤0.010 | |

OVERVIEW

Valve material is a necessary material for the production of

gasoline engine and diesel engine inlet and exhaust valve, but also

the key material in the whole engine. In order to meet the needs of

different types of internal combustion engines, developed countries

in the world are constantly developing all kinds of new exhaust

valve materials.

Inlet and exhaust valve in high temperature gas corrosion, high

load and high stress action and other harsh environment, the valves

has to withstand the temperature of up to 600-800°C. Alloy 80A and

Alloy 751 are two commonly used valve alloys. Alloy 80A gets more

and more attention for its high temperature performance with the

large quantity use of it. The microstructure and properties of

Alloy 80A were studied, and it was found that the increase of Ti/Al

ratio significantly improved the mechanical properties at room

temperature. When Ti/Al is relatively low, β-NiAl phase is

precipitated out of the crystal, resulting in high temperature

fracture of the material.

Alloy LF2 is an economical Fe-Ni base aging strengthened Alloy with

excellent high temperature gas corrosion resistance and high

temperature resistance performance. It has the almost the same high

temperature performance as Alloy 80A and Alloy 751, which are

widely used in foreign countries. As the Ni content decreased from

70% to 30%, the cost was greatly reduced. The valve made of this

alloy has been widely used in 4B locomotive by Dongfeng, and 240B

locomotive made by CRRC Dalian Locomotive & Vehicle Co., Ltd., and

Beijing railway bureau tianjin locomotive and vehicle parts

Co.,Ltd, and other high power heavy-duty diesel engines. It

operates quite wel. Also they are widely used in heavy-duty

commercial vehicles and heavy-duty trucks. Alloy LF2 is a kind of

valve alloy with great market potential. However, with the

continuous increase of internal combustion engine parameters and

the increase of exhaust temperature and exhaust purification

standard, more stringent requirements are put forward for the

performance of valve alloy.

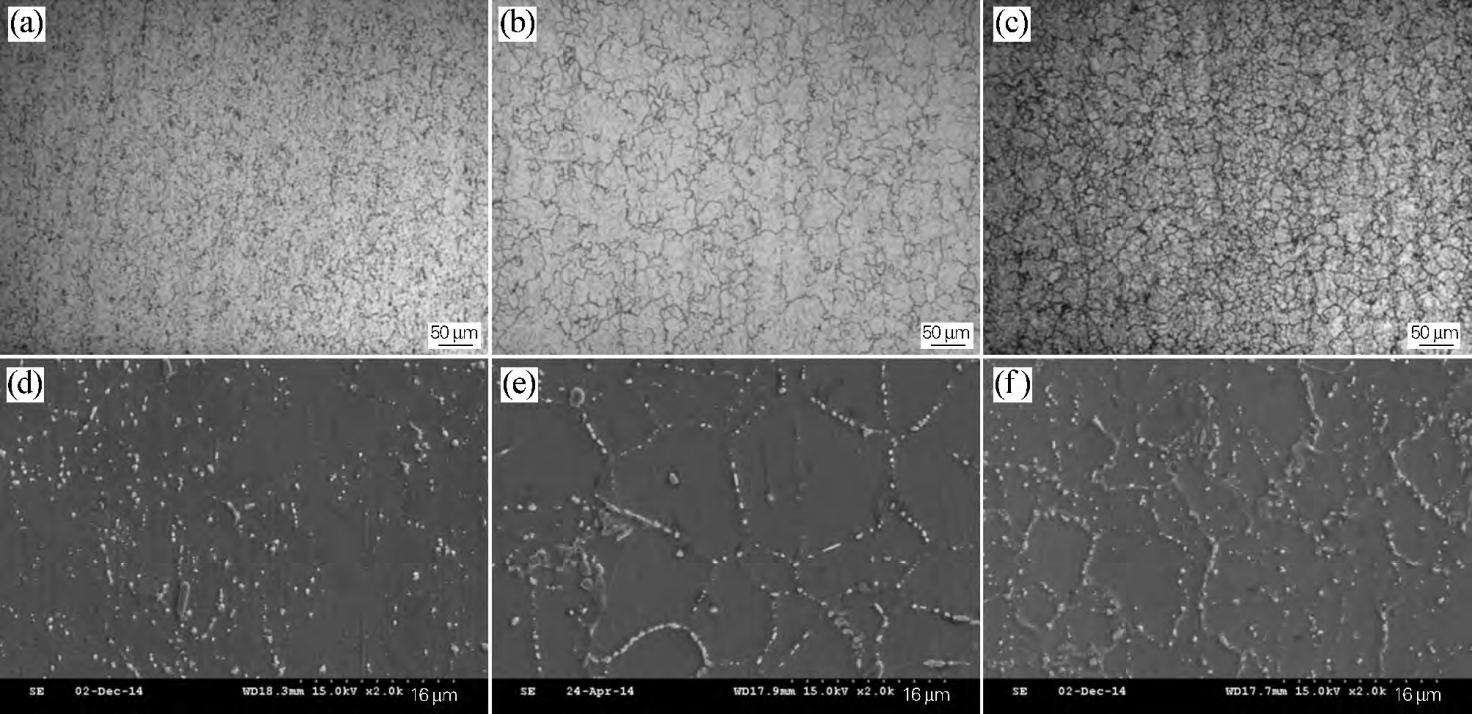

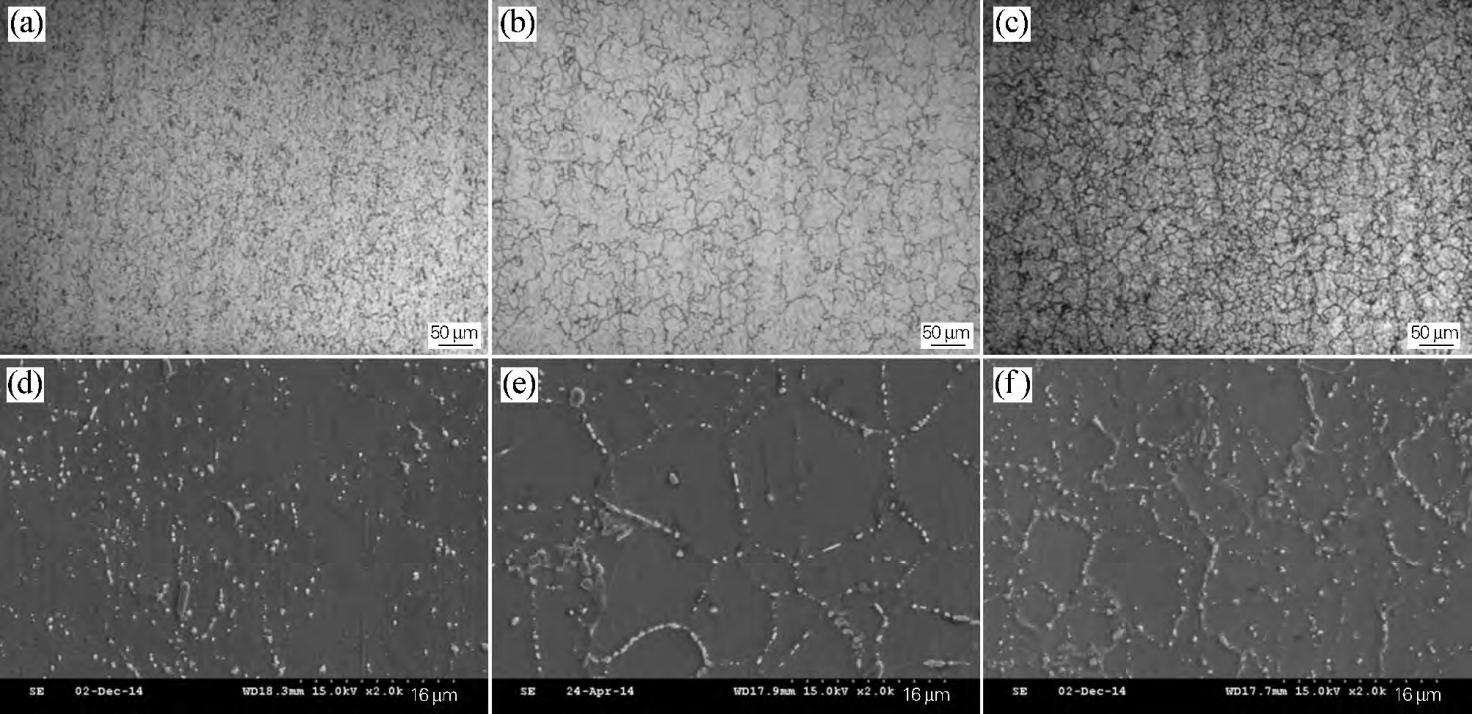

METALLOGRAPHY

The matrix of LF2 alloy is austenite. γ′phase, MC phase, Laves

phase and sigma phase are the main precipitated phases.

Chemical phase analysis of the tested alloys ( mass fraction %)

| Precipitated phase | Mass fraction % | Main chemical composition% |

| γ' | 6.051 | 0.168Nb |

| 0.655Ti |

| 0.304Al |

| Laves | 1.155 | 0.323Nb |

| 0.113Ti |

| 0.085Cr |

| MC | 0.302 | 0.131Nb |

| 0.118Ti |

| 0.048C |

Fig.1 Microstructure of Alloy LF2 under different solution

temperatures (a,d) 950℃; (b,e) 990℃; (c,f) 1070℃

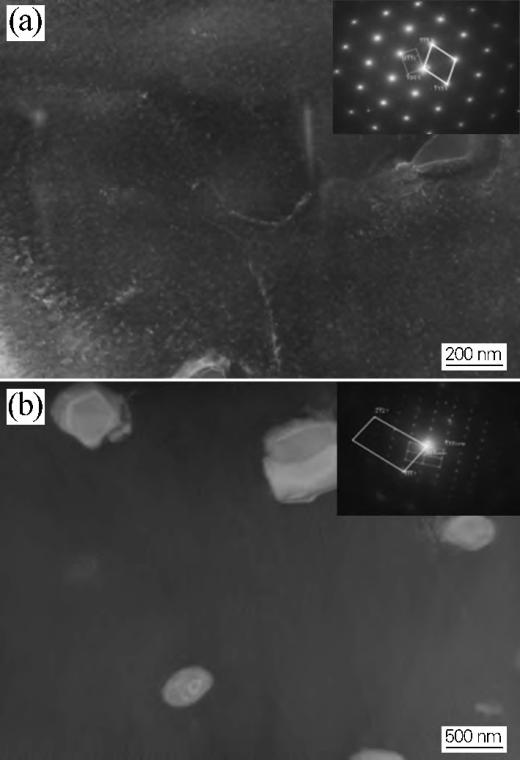

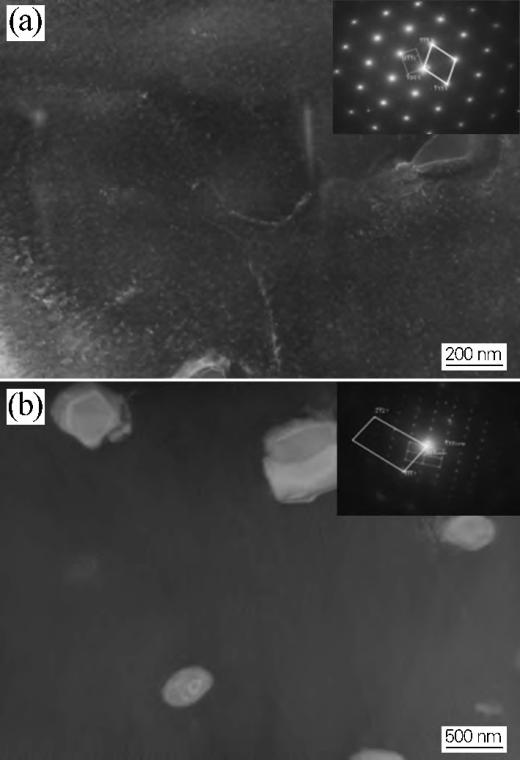

Fig.2 TEM images of precipitated phase and selected area

diffraction patterns (SAD) after 990℃ x 1 h,WQ + 760℃ x 10 h,AC,

(a) γ' phase; (b) Laves phase

Fig.3 SEM image (a) and EDS spectrum (b) of the MC phase after 990℃

x 1 h,WQ + 760℃ x 10 h,AC

HEAT TREATMENT

Solid solution treatment

The purpose of solid solution treatment is to dissolve the second

phase of carbides and γ' phase in the matrix, so as to obtain

uniform oversaturated solid solution, which is conducive to

re-precipitation of carbides with uniform distribution of fine

particles and gamma' and other strengthening phases during aging

process, and at the same time to eliminate the stress generated in

the cold and hot processing process and promote recrystallization

of the alloy. Secondly, solid solution treatment is also to obtain

the appropriate grain size to ensure the stability of the alloy

performance.

The optimal solid solution temperature for Alloy LF2 is 990°C, 1

hour, water cooling.

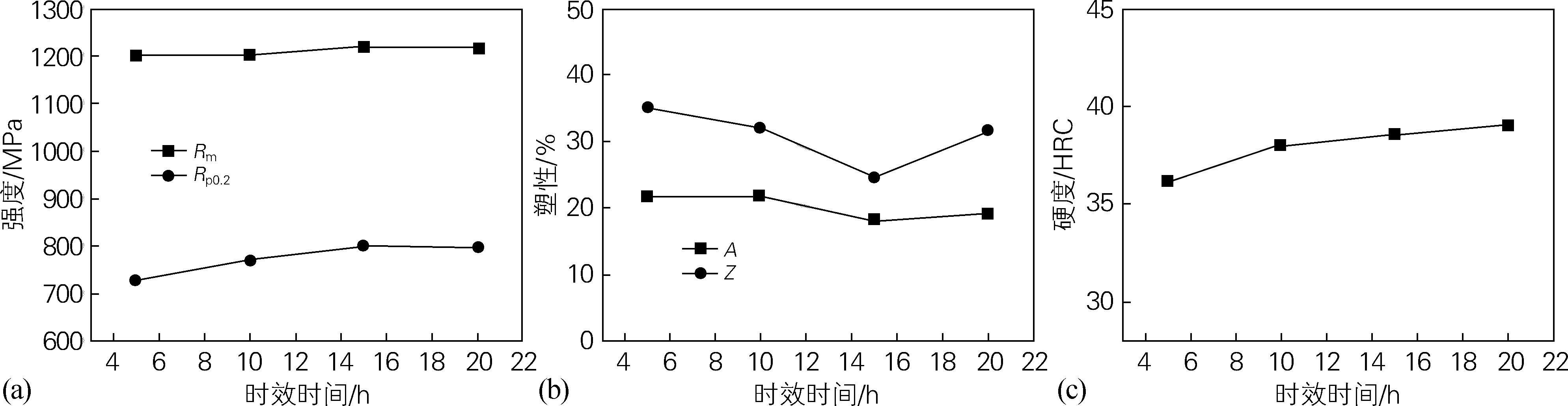

Aging treatment

For the purpose of optimal mechanical properties and

microstructure, the optimal aging treatment shall be at 760℃,

holding for 10 hours, and air cooling.

Fig.4 Microstructure of Alloy LF2 under different aging

temperatures (solution treated at 990℃ for 1h)

(a,d) 680℃, (b,e) 760℃, (c,f) 800℃

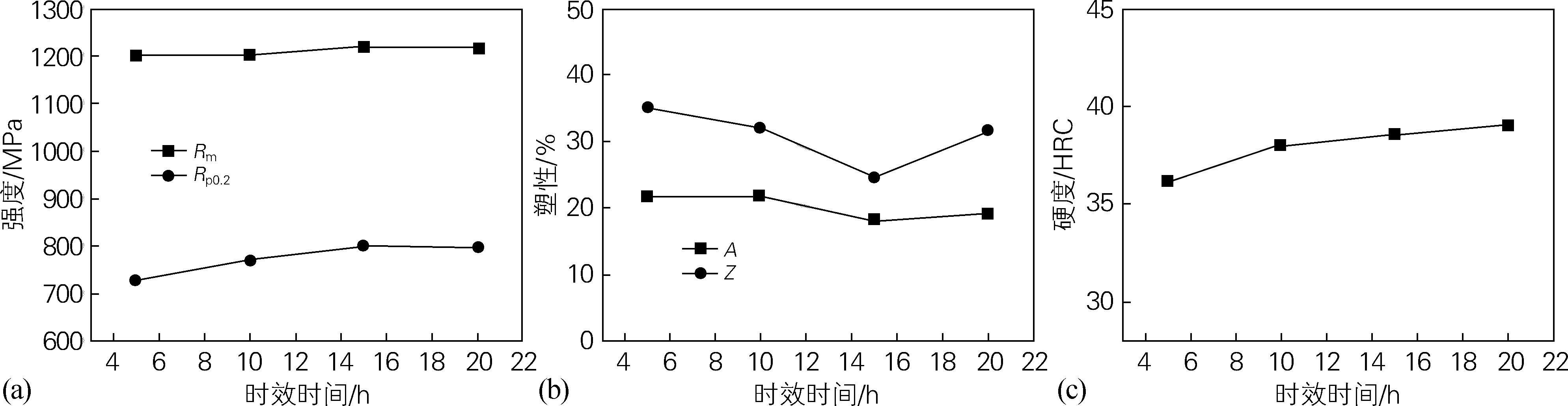

Fig.5 Mechanical properties of Alloy LF2 under different aging time

(a) strength, (b) ductility, (c) hardness

MECHANICAL PROPERTIES

Heat treatment:Solid solution annealing at 990℃ x 1h, WQ, aging at

760℃ x 10h, AC.

| Tensile strength Rm | Yield strength Rp0.2 | Elongation | Reduction area |

| MPa | MPa | % | % |

| 1201 | 772 | 21.8 | 32 |

COMPETITIVE ADVANTAGE:

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patent technologies.

(4) Average grain size 9 or finer.

(5) High performance

BUSINESS TERM

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Water prevent, seaworthy transport, non-fumigation wooden box |

| Mark | As per order |

| Delivery Time | 60-90 days |

| Payment Terms | T/T, L/C at sight, D/P |

| Supply Ability | 100 metric tons per month |