Alloy 31V (31V alloy) for heavy-duty internal combustion engine

exhaust valves

PRODUCT

Alloy 31V (31V alloy) for heavy-duty internal combustion engine

exhaust valves.

EQUIVALENT DESIGNATION

UNS N07032, CarTech® 31V Alloy, Pyromet® 31V

PRODUCT FORM

Round bar, forgings, forging stock etc.

APPLICATION

Because of its excellent balance of properties, alloy 31V has been

considered a candidate for many demanding applications, including

rapid fire military gun barrels, hardware in coal gasification

units and exhaust valves in heavy-duty internal combustion engines.

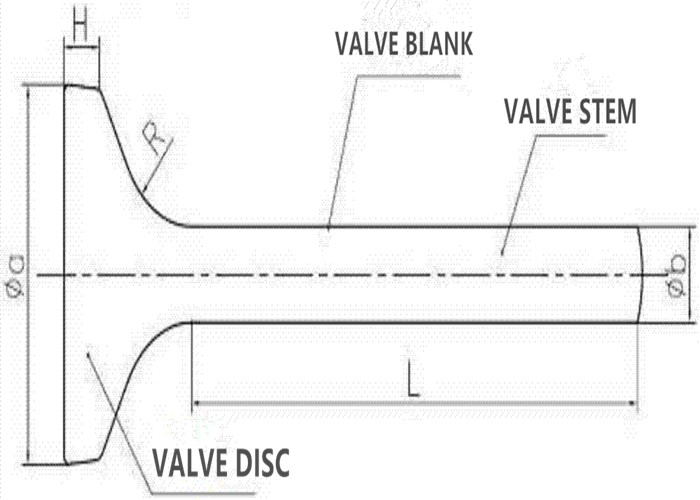

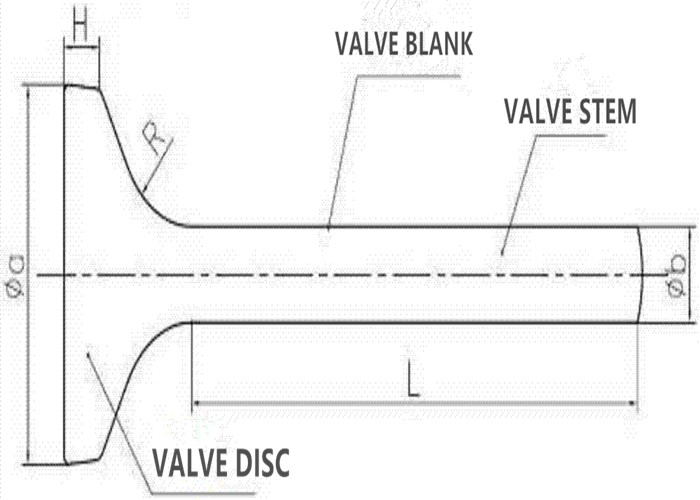

SKETCH OF EXHAUST VALVE

PRODUCTION PROCEDURE OF EXHAUST VALVE

Blanking → Electric heating upsetting forging of head blank → Heat

treatment of head blank and rod → Friction welding → Rough turning

or grinding → Finish turning → Cut fixed length → Semi-fine

grinding the stem → The valve stem chrome plating → Fine grinding

the stem → NDT of the finished valve → Delivery

SURFACE CONDITION OF EXHAUST VALVE

PRODUCTION SITE OF EXHAUST VALVE

OVERVIEW

Alloy 31V is a sulfidation and corrosion resistant precipitation

hardenable alloy possessing an unusual combination of corrosion

resistance and strength to temperatures as high as 1500°F (816°C).

This alloy displays good resistance to hot sulfidizing and

oxidizing environments such as those encountered in diesel engine

service, as well as sour environments such as those encountered in

deep sour gas and oil wells.

CHEMICAL COMPOSITION (wt%):

Table 1

| Fe | Ni | B | Cr | Ti | Nb | Mo |

| Balance | 57.00 | 0.005 | 22.70 | 2.30 | 0.85 | 2.00 |

| C | Al | Mn | Si | P | S | |

| 0.04 | 1.30 | ≤0.20 | ≤0.20 | ≤0.015 | ≤0.010 | |

PHYSICAL PROPERTIES

Density: 8.01 g/cm³ (0.289 lb/in³)

Melting range: 2250 - 2420°F (1232 - 1327°C)

MECHANICAL PROPERTIES

Typical room and elevated temperature mechanical properties

Specimen: 0.75 in (19mm) round bar

Heat treatment:

1 Heat treated at 2050°F(1121°C) 1 hour, AC, 1550°F(843°C) 4 hours,

AC, 1350°F(732°C) 4 hours, AC

2 Heat treated at 2050°F(1121°C) 1 hour, AC, 1300°F(704°C) 24 hours

3 Heat treated at 1875°F(1024°C) 1 hour, oil quenched,

1300°F(704°C) 24 hours

| Heat treatment | Test temperature | 0.2% Yield strength | Ultimate tensile strength | % Elongation in 4D | % Reduction of area |

| °F | °C | ksi | MPa | ksi | MPa |

| 1 | 70 | 21 | 105 | 724 | 176 | 1214 | 25 | 27.4 |

| 2 | 70 | 21 | 100 | 690 | 166 | 1145 | 33.9 | 36.5 |

| 3 | 70 | 21 | 122 | 841 | 181 | 1248 | 30 | 38.5 |

| 1 | 1000 | 538 | 95 | 655 | 157 | 1083 | 19.2 | 30.6 |

| 2 | 1000 | 538 | 91 | 627 | 141 | 972 | 31.4 | 45.2 |

| 3 | 1000 | 538 | 108 | 745 | 155 | 1069 | 25.1 | 45.6 |

| 1 | 1200 | 649 | 94 | 648 | 153 | 1055 | 20 | 29.3 |

| 2 | 1200 | 649 | 92 | 634 | 139 | 958 | 22.8 | 33.7 |

| 3 | 1200 | 649 | 111 | 765 | 152 | 1048 | 18.5 | 25.2 |

| 1 | 1400 | 760 | 95 | 655 | 110 | 758 | 25 | 33.4 |

| 2 | 1400 | 760 | 82 | 565 | 112 | 772 | 23.8 | 25.2 |

| 1 | 1500 | 816 | 84 | 579 | 86 | 593 | 28.4 | 37.1 |

| 2 | 1500 | 816 | 79 | 544 | 94 | 648 | 24.6 | 30.6 |

CORROSION RESISTANCE

Laboratory crucible tests aimed at assessing the capability of

alloy 31V to withstand high temperature sulfidation attack were

carried out in a mixture of 10 CaSO4 - 6 BaSO4 - 2 Na2SO4 - 1 C at

1600°F (871°C) for up to 80 hours. The results shown in the

hyperlink titled "Comparative Sulfidation Test Results-Various

Alloys" indicate that alloy 31V has superior resistance compared to

commercial diesel valve alloys like alloys 751 and 80A, which

suffered catastrophic attack. All three alloys have excellent

resistance to hot corrosion by lead oxide at 1675°F (913°C).

In a molten mixture of 90% Na2SO4 / 10% NaCl at 1700°F (927°C) /

100 hours, alloy 31V showed only slight attack while alloy 751

suffered catastrophic attack.

Evaluations in both laboratory and field environments have been

conducted to establish alloy 31V as a candidate for consideration

as a sulfide stress cracking resistant material for oil field

applications in sour environments.

Comparative tests have shown that alloy 31V is superior to alloy

X-750 (an established alloy for sour service) in the NACE TM-01-77

solution, which consists of an acidified, deoxygenated sour brine

solution saturated with hydrogen sulfide.

Comparative sulfication test results- various alloys at

1600°F(871°C)

| Alloy | Duration hours | Weight loss g/dm2 |

| Alloy 80A | 5 | 1 |

| 30 | 72 |

| 80 | Catastrophic(>100) |

| Alloy 751 | 5 | 1 |

| 30 | 58 |

| 80 | Catastrophic(>100) |

| Alloy 31V | 5 | 0 |

| 30 | 1 |

| 80 | 52 |

HEAT TREATMENT

Solution treatment

A lower solution temperature, 1875°F (1025°C), will result in

somewhat finer grain size and is sometimes employed to optimize

properties below 1200°F (649°C).

Age

Solution treated stock may be given a single or double age for

optimum compatibility with manufacturing processes. The single-age

cycle is 1300°F (704°C) for 24 hours, followed by an air cool. The

double-age cycle includes a stabilizing age in the range from

1550/1600°F (843/871°C) for 4 hours, air cool, plus a final age at

1350°F (732°C) for 4 hours, air cool.

WORKING INSTRUCTION

Hot working

Alloy 31V can be hot worked within the temperature range of

1800/2100°F (980°/1150°C). Careful control of the forging

temperature and frictional heat build-up should be maintained.

Large amounts of deformation below 1800°F (980°C) should be

avoided.

Forgings may be air or fan cooled. Water quenching should be

avoided, especially for large sections.

Machinability

The machinability of this alloy is similar to other iron-nickel

base precipitation hardened alloys, such as Alloy X-750.

The alloy can be machined in either the solution annealed or age

hardened condition. Machine tools should have ample power, and

cutting speeds should be slow.

For better chip action on chip breakers and an improved finish, use

material in the age hardened condition.

COMPETITIVE ADVANTAGE:

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patent technologies.

(4) Average grain size 9 or finer.

(5) High performance

BUSINESS TERM

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Water prevent, seaworthy transport, non-fumigation wooden box |

| Mark | As per order |

| Delivery Time | 60-90 days |

| Payment Terms | T/T, L/C at sight, D/P |

| Supply Ability | 100 metric tons per month |