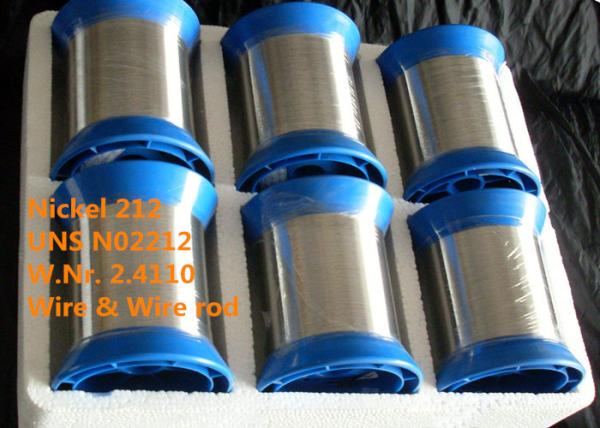

Nickel 212, UNS N02212 W.Nr. 2.4110 sheet, strip, wire, bar, tube

etc for electronic parts

1 PRODUCT

Nickel 212, UNS N02212 W.Nr. 2.4110 semi-products for electronic

parts.

Nickel 212 is available as sheet, strip, wire, bar, tube etc.

2 EQUIVALENT DESIGNATION

UNS N02212, W.Nr. 2.4110

3 APPLICATION

Nickel 212 has been used in various electronic applications such as

electrical lead wires, supporting components in lamps and

cathode-ray tube, lamp and electronic valve support assemblies,

electrodes in glow-discharge lamps, and ignition contacts etc.

4 OVERVIEW

Nickel

Commercially pure or low-alloy nickel has characteristics that are

useful in several fields, notably chemical processing and

electronics. Nickel is highly resistant to various reducing

chemicals and is unexcelled in resistance to caustic alkalies.

Compared with nickel alloys, commercially pure nickel has high

electrical and thermal conductivity. It also has a high Curie

temperature and good magnetostrictive properties. Annealed nickel

has a low hardness and good ductility and malleability. Those

attributes, combined with good weldability, make the metal highly

fabricable. Nickel has a relatively low work-hardening rate, but it

can be cold worked to moderately high strength levels while

maintaining ductility.

Nickel 212

Nickel 212 is available as sheet, strip, tube, wire (round, flat,

shaped etc), bar etc.

5 CHEMICAL COMPOSITION

Table 1 (wt%)

| Ni+Co | C | Cu | Fe | Mg | Mn | S | Si | Co |

| ≥97.0 | ≤0.10 | ≤0.20 | ≤0.25 | ≤0.20 | 1.5-2.5 | ≤0.006 | ≤0.20 | ≤1.0 |

6 PHYSICAL PROPERTIES

Density: 8.86 g/cm3 (0.320 lb/in3)

Melting range: 1435-1446°C (2615-2635°F)

Specific heat: 430 J/kg•°C (0.103 Btu/lb•°F)

Coefficient of Expansion : (68-212°F / 20-100°C): 7.2x10-6 in/in•°F (12.9um/m•°C)

Thermal Conductivity: 305 Btu•in/ft2•h•°F (44.0W/m•°C)

Electrical Resistivity: 66 ohm•circ mil/ft (0.109uohm•m)

Shear modulus: 78 kN/mm²(11313 ksi)

Elasticity modulus: 196 kN/mm²(28400 ksi)

7 MECHANICAL PROPERTIES

Thanks to the addition of manganese, the strength is stronger than

Nickel 200.

Tensile strength and elongation at temperatures above 315°C (600°F)

dropped significantly.

Working temperature is related to environment, load and size range.

| Condition | Approximate tensile strength |

| MPa | ksi |

| Annealed | 450-550 | 65-80 |

| Cold drawn hard | 750-950 | 109-138 |

Norminal mechanical properties as per DIN 17750 (Plate, strip and

sheet)

| Code | W.Nr.No. | Condition | Heat treatment | Strip thickness mm | Plate thickness mm | Rm N/mm2 min. | Rp0.2 N/mm2 min. | Rp1.0 N/mm2 min. | Elongation A5 % min. | Brinel Hardness HBW 2.5/62.5 |

| max. | about |

| NiMn2 | 2.4110 | F40 | Annealed | 0.20-2.50 | / | 400 | 140 | / | 40 | 130 | / |

| F54 | Half hard | 0.20-2.50 | / | 540 | 340 | / | 20 | / | 160 |

| F74 | Hard | 0.20-2.50 | / | 740 | 600 | / | 2 | / | 220 |

Norminal mechanical properties as per DIN 17753 (Wire)

| Code | W.Nr.No. | Condition | Heat treatment | Dia.mm | Rm N/mm2 min. | Elongation |

| AL=100 % min. | A5 % min. |

| NiMn2 | 2.4110 | F40 | Annealed | 0.10≤d≤0.30 | 400 | 15 | / |

| F40 | Annealed | 0.30<d≤0.80 | 400 | 20 | / |

| F40 | Annealed | 0.80<d≤3.00 | 400 | 30 | / |

| F40 | Annealed | 3.00<d≤8.00 | 400 | / | 30 |

8 STANDARD SPECIFICATION

DIN 17741 Low-alloy wrought nickel alloys - Chemical composition

DIN 17750 Plates, strips and sheets of wrought nickel and nickel

alloys - properties

DIN 17751 Tubes of wrought nickel and nickel alloys - Properties

DIN 17752 Rod and bar of wrought nickel and nickel alloys -

Properties

DIN 17753 Wires of wrought nickel and nickel alloys - Properties

9 COMPETITIVE ADVANTAGE:

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patented technologies.

(4) Ultra-purity smelting process: VIM + IG-ESR + VAR

(5) Excellent high performance.

10 BUSINESS TERM

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Water prevent, seaworthy transport, mill’s export standard packing |

| Mark | As per order |

| Delivery Time | 60-90 days |

| Payment Terms | T/T, L/C at sight, D/P |

| Supply Ability | 100 metric tons / Month |