Alloy waspaloy round bar, forgings, extruded sections, wire,

fastener for gas turbine engine components

1 PRODUCT

Alloy waspaloy round bar, forgings, extruded sections, wire,

fastener for gas turbine engine components, airframe assemblies and

missile systems etc.

2 EQUIVALENT DESIGNATION

UNS N07001, AISI NO.685, W.Nr. 2.4654, CarTech® Waspaloy, Harnes®Waspaloy, NI-P101HT

3 APPLICATION

Waspaloy is used for gas turbine engine components that call for

considerable strength and corrosion resistance at high operating

temperatures. Current and potential applications include compressor

and rotor discs, shafts, spacers, seals, rings and casings,

fasteners and other miscellaneous engine hardware, airframe

assemblies and missile systems.

The alloy has been used for gas turbine engine parts which require

considerable strength and corrosion resistance at temperatures up

to 1600°F (871°C).

4 CHEMICAL COMPOSITION (wt%):

| Fe | Ni | Co | Cr | Ti | B | Mo | Zr |

| ≤2.00 | Balance | 12.00-15.00 | 18.0-21.0 | 2.75-3.25 | 0.003-0.008 | 3.50-5.00 | 0.02-0.12 |

| C | Al | Mn | Si | P | S | Cu | |

| 0.02-0.10 | 1.20-1.50 | ≤0.50 | ≤0.75 | ≤0.020 | ≤0.020 | ≤0.10 | |

5 PHYSICAL CONSTANTS

Density: 8.19 g/cm³ (0.296 lb/in³)

Melting range: 1330-1360°C (2425-2475°F)

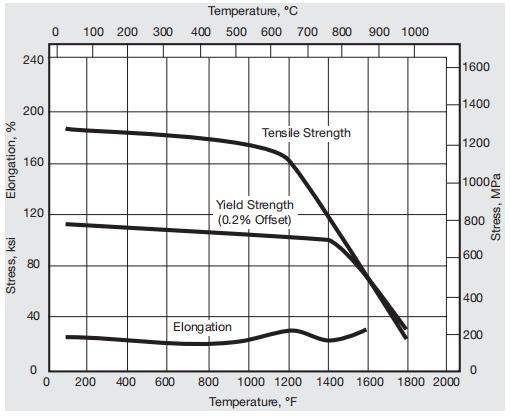

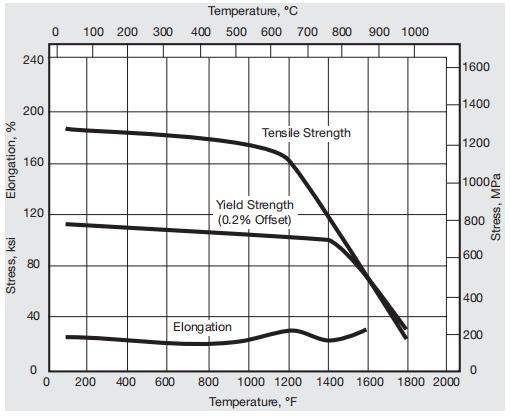

6 MECHANICAL PROPERTY

Typical mechanical properties (Heat treatment A)

7 CORROSION RESISTANCE

Waspaloy displays excellent resistance to corrosion by combustion

products encountered in gas turbines and aircraft jet engines at

temperatures up to 1600°F (871°C). Intergranular oxidation occurs

at temperatures above 1600°F (871°C).

The alloy's oxidation resistance is good under conditions of

frequent thermal cycling, and in continuous exposure to

temperatures up to 1900°F (1038°C). It has performed well in

atmospheres found in gas turbine engine service and in salt spray

environments. Solution-treated material offers the best levels of

corrosion resistance.

8 HEAT TREATMENT

Waspaloy is heat treated in a three-step sequence encompassing

solution treatment, stabilization and age- hardening.

A: For optimum high-temperature creep and stress-rupture

properties.

Solution treatment - heat at 1080°C (1975°F)/4h/AC to produce

hardness of 20-25 Rockwell C. Stabilization - reheat to 845°C

(1550°F)/24h/AC. Age harden - reheat to 760°C (1400°F)/16h/AC to

produce hardness of 34-40 Rockwell C.

B: For optimum room and high temperature tensile properties.

Solution treatment - heat at 995-1035°C (1825-1895°F)/4h/oil

quench. Stabilization - reheat to 845°C (1550°F)/4h/AC.

Age harden - reheat to 760°C (1400°F)/16h/AC to produce hardness of

34-44 Rockwell C.

9 WORKING INSTRUCTION

Hot working

Hot working is usually conducted in the temperature range

1800-2150°F (982-1177°C). This avoids rapid work hardening,

possible cracking below 980°C (1800°F), and hot shortness above

1180°C (2150°F).

Cold working

The alloy may be cold worked by hydroforming, drawing, spinning,

bending, roll forming, etc. It is considerably stronger than the

AISI 300 series stainless steels at room temperature. Annealed

alloy bar has also been successfully cold-headed into fastener

configurations. Intermediate annealing is normally required because

the alloy work hardens very rapidly.

10 PRODUCT FORM

Round bar, forgings, forging stock, extruded sections, billet,

strip, wire and wire rod etc.

11 STANDARD SPECIFICATION

Rod, Bar, Wire and Forging stock

ASTM B637 / ASME SB637 Billert, Rod & Bar, forgings

BS EN 2930 Bolts

SAE AMS 5704 Billert, Rod & Bar, forgings

SAE AMS 5706 Billert, Rod & Bar, forgings

SAE AMS 5707 Billert, Rod & Bar, forgings

SAE AMS 5708

SAE AMS 5709

SAE AMS 5828 Bare Welding Rods & Wire

SAE MAM 5706

SAE AMS 7471

AECMA PrEN 2193

AECMA PrEN 2194

AECMA PrEN 2406

AECMA PrEN 2958

AECMA PrEN 2959

AECMA PrEN 2960

AECMA PrEN 3220

Plate, Sheet and Strip

SAE AMS 5544 Sheet, Plate & Strip

AECMA PrEN 2195

12 COMPETITIVE ADVANTAGE

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patented technologies.

(4) High performance.

13 BUSINESS TERM

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Water prevent, seaworthy transport, non-fumigation wooden box |

| Mark | As per order |

| Delivery Time | 60-90 days |

| Payment Terms | T/T, L/C at sight, D/P |

| Supply Ability | 100 metric tons / Month |