Alloy 105, Nimonic® alloy 105 for ultra-supercritical thermal

turbine blade, forgings, ring, fastener etc

1 PRODUCT

Alloy 105, Nimonic® alloy 105 for ultra-supercritical thermal

turbine blade, aero-engine turbine blades, forgings, ring, discs,

sections, bolts and fasteners, etc.

2 EQUIVALENT DESIGNATION

GH4105, W.Nr.2.4634, NiCo20Cr15MoAlTi(DIN), HR3(BS)

3 APPLICATION

Alloy 105 is used for thermal turbine blades, materials for key

high temperature components of ultra-supercritical thermal turbine,

discs, aero-engine turbine blades, forgings, ring, sections, bolts

and fasteners, etc.

4 CHEMICAL COMPOSITION (wt%):

| Fe | Ni | Co | Cr | Ti | Cu | Mo | Zr |

| ≤1.0 | Balance | 18.0-22.0 | 14.0-15.7 | 1.18-1.50 | ≤0.20 | 4.5-5.5 | 0.070-0.15 |

| C | Al | Mn | Si | P | S | B | |

| 0.05-0.17 | 4.5-4.90 | ≤0.40 | ≤0.25 | ≤0.015 | ≤0.010 | 0.003-0.010 | |

5 PHYSICAL CONSTANTS

Density: 8.01 g/cm³ (0.289 lb/in³)

Melting Range: Liquidus temperature 1345°C, solidus temperature

1290°C.

6 MECHANICAL PROPERTY

Tensile properties: extruded bar subsequently forged

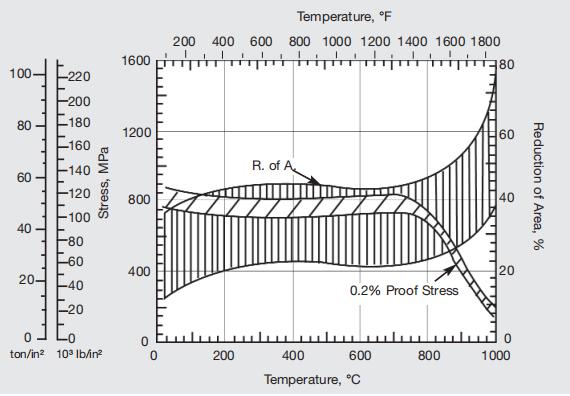

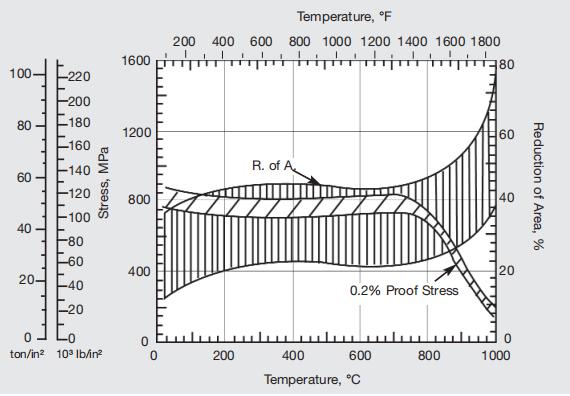

The data given in Table below and presented graphically in Figures

1 and 2 represent the tensile properties for extruded bar

subsequently forged after the 3-stage heat treatment.

Strain rate 0.005/min to proof stress (at room temperature),

0.002/min to proof stress (at elevated temperatures) and 0.1/min

thereafter.

Heat treatment 4 h/1150°C/AC + 16 h/1050-1065°C/AC + 16 h/850°C/AC

| Temperature °C | 0.1% proof stress | 0.2% proof stress | Tensile strength | Elongation on 5.65 √So, % | Reduction of area % |

| MPa | MPa | MPa |

| 20 | 796 | 827 | 1180 | 16 | 16 |

| 100 | 760 | 793 | 1185 | 21 | 24 |

| 200 | 745 | 774 | 1188 | 24 | 34 |

| 300 | 739 | 766 | 1162 | 20 | 24 |

| 400 | 732 | 763 | 1126 | 23 | 33 |

| 500 | 748 | 782 | 1148 | 23 | 31 |

| 600 | 735 | 769 | 1111 | 22 | 32 |

| 700 | 739 | 768 | 1075 | 26 | 33 |

| 800 | 680 | 714 | 836 | 24 | 34 |

| 900 | 390 | 411 | 491 | 28 | 38 |

| 1000 | 152 | 156 | 189 | 43 | 60 |

| 1100 | 28 | 31 | 56 | 132 | 99 |

Figure 1 Heat treatment 4h/1150°C/AC + 16h/1050-1065°C/AC +

16h/850°C/AC

Figure 2 Heat treatment 4h/1150°C/AC + 16h/1050-1065°C/AC +

16h/850°C/AC

7 CORROSION RESISTANCE

Oxidation in Air

Table 7-1 Continuous Heating, descaled weight loss (mg/cm²) after

100 hours at

| 800°C | 900°C | 950°C | 1000°C | 1100°C |

| 0.11 | 0.49 | 0.99 | 1.43 | 6.41 |

Table 7-2 Intermittent heating (Cooling to room temperature every

24 hrs), descaled weight loss (mg/cm²) after 100 hours at

| 800°C | 900°C | 950°C | 1000°C | 1100°C |

| — | 1.19 | 1.59 | 1.61 | 13.3 |

Table 7-3 Cyclic Heating (15 min in furnace, 5 min outside furnace)

| Temperature | Time to onset of spalling (h) at max cycle temperature of | Rate of spalling (mg/cm²/h) at max cycle temperature of | Weight change in 100 h (mg/cm²) at max cycle temperature of |

| °C | °C | °C | °C |

| 890 | >1000 | — | 0.66 |

| 910 | >1000 | — | 1.05 |

| 990 | 600 | 0.15 | -51.9 |

| 1010 | 300 | 0.408 | -229 |

| 1090 | 150 | 0.946 | -748 |

| 1110 | 75 | 1.17 | -955 |

Table 7-4 Resistance to atmospheres containing SO2

| Atmosphere | Descaled weight loss (mg/cm²) after 1000 hours at |

| 600°C | 700°C | 800°C | 1000°C |

| 3% SO2-Argon | 1.6 | 8.7 | 15 | — |

| 3% SO2-Air | 2.3 | 1.1 | 0.6 | 0.6 |

| 3% SO2-5% O2-Argon | 2.1 | 0.5 | 0.6 | 2.1 |

8 WORKING INSTRUCTION

Hot working

Alloy 105 may be hot worked in the temperature range 1050-1200°C.

Annealing

Interstage annealing of Alloy 105 should be carried out at 1150°C

followed by air cooling of fluidized bed quenching. Water quenching

is not recommended as severe surface cracking may result from

thermal shock.

Machining

Alloy 105 should be in the fully heat-treated condition for all

machining operations. The high hardness range 320-385 HV,

necessitates the use of tungsten carbide tipped tools. High speed

steel shock-proof tools can be used if the cut is of an

intermittent nature.

Heat treatment

The heat treatment recommended is dependent on the intended service

condition.

Two heat treatments are recommended as follows:

(a) 4 h/1150°C/AC+16 h/1050-1065°C/AC+16h/850°C/AC

(b) 4 h/1125°C/AC+16 h/850°/AC

In general, heat treatment (a) is intended for optimum long-term

creep strength and ductility at operating temperatures in the range

850-950°C. Heat-treatment (b) may be used where long-term

properties are not of paramount importance and tensile strength,

elongation and impact strength may be enhanced for operating

temperatures up to 700°C. When applying heat-treatment (b), it is

essential to ensure that cooling from 1125°C takes place freely and

is not delayed due to close packing of components.

Examples of the use of these heat treatments are as follows:

(a) Turbine blades, discs, forgings and ring sections, all of which

may be produced from as extruded, as forged or subsequently cold

worked starting stock

(b) Bolts and fasteners for which extruded and cold worked bar or

section is recommended as starting stock.

9 STANDARD SPECIFICATION

BS. HR3 billets, bars and forgings

AICMA Ni-P61-HT billets, bars and forgings

Swedish Defence Material Administration MH.14 forged bar

DIN designation NiCo20Cr15MoAlTi forged bar

AFNOR NCKD 20ATv AECMA PrEn 2179-2181

10 COMPETITIVE ADVANTAGE

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patent technologies.

(4) High performance.

11 BUSINESS TERM

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Water prevent, seaworthy transport, non-fumigation wooden box |

| Mark | As per order |

| Delivery Time | 60-90 days |

| Payment Terms | T/T, L/C at sight, D/P |

| Supply Ability | 200 metric tons / Month |